When it comes to paint stripping, conventional methods like chemical solutions, abrasive blasting, or heat guns often pose environmental hazards, cause material damage, or are just plain messy. With LaserChina’s state-of-the-art laser paint stripping solutions, you can now experience an efficient, eco-friendly, and precision-driven method for removing paint from various surfaces.

The Future of Paint Stripping is Here

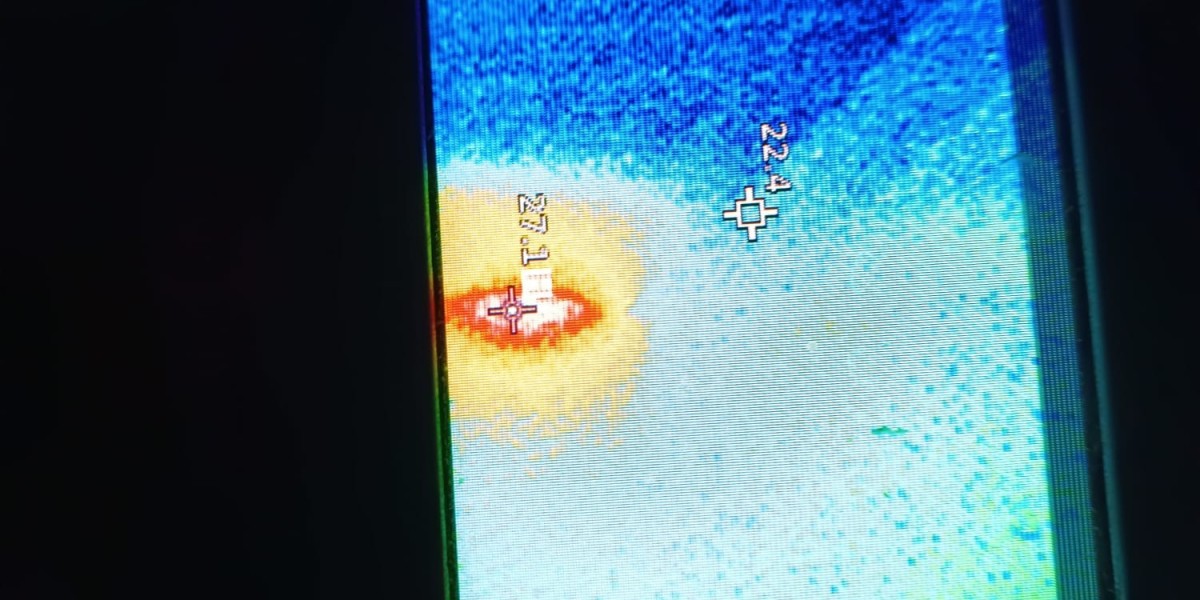

LaserChina’s laser paint stripping systems harness the power of concentrated laser energy to safely and effectively remove coatings, paint, rust, and other contaminants from metal, plastic, and composite surfaces. Whether you’re dealing with aerospace components, automotive parts, or industrial machinery, laser paint stripping offers a non-contact and non-abrasive solution, protecting the integrity of the underlying material.

The laser technology works by emitting a highly focused beam of light that vaporizes paint or coatings without using any chemicals or abrasives. This method ensures not only a cleaner working environment but also faster, more precise results.

Key Benefits of LaserChina’s Laser Paint Stripping

1. Eco-Friendly Process:

Unlike chemical strippers that release toxic fumes or powders into the air, laser paint stripping from LaserChina produces minimal waste. There are no hazardous chemicals, reducing environmental impact and ensuring safer working conditions for operators.

2. Precision and Control:

LaserChina’s laser paint stripping solutions allow operators to remove paint in a controlled, localized manner. You can fine-tune the laser settings to suit specific materials or coating types, ensuring a smooth, clean finish without damaging the substrate.

3. Cost-Effective and Time-Saving:

Laser paint stripping reduces labor costs and downtime significantly. Since the process is automated and does not require manual scrubbing, sanding, or chemical treatments, it’s faster and more efficient than traditional paint removal methods.

4. Versatility Across Industries:

LaserChina’s technology is versatile enough to be used in various industries, including aerospace, automotive, marine, and industrial manufacturing. Whether you need to strip paint from an aircraft fuselage or remove coatings from large industrial machines, our systems can handle it all.

5. Minimal Surface Damage:

Since the laser only affects the top layers of the material, the risk of damaging the surface beneath is significantly reduced. This is particularly valuable in industries where precision and material integrity are critical, such as aerospace or defense.

Why Choose LaserChina?

LaserChina is a global leader in laser solutions, offering cutting-edge laser paint stripping systems designed for durability, efficiency, and precision. Our team of experts provides tailored solutions to meet the specific needs of each customer, ensuring you get the most effective and reliable equipment for your operations.

Embrace the future of paint removal with LaserChina’s laser paint stripping technology—the ultimate solution for a cleaner, safer, and more efficient process.