We measure floor profile, earlier than & after DFT, and take a look at for holidays upon request. Moisture-cured urethane coatings may be applied almost any time of the yr, besides during very chilly temperatures, when dew or condensation could freeze on tank surfaces. Rust is a routine drawback, not to mention cleansing away other contaminants, which will range relying on location and surrounding space. CPI Restoration provides professional restoration and preventive upkeep companies to business properties in the Mid-Atlantic Region. With more than 30 years of professional experience, we work with current buildings and new construction to gauge your needs and necessities, set up your price range, and choose the best choices for our prospects.

A Guide to Industrial Painting Methods for Coating Water, Fuel, and Storage Tanks

This article has been created to give you a little steering on which paints are good for metal. We take the time to understand your wants and your vision of the project when it is accomplished. Our preliminary quote shall be primarily based on the knowledge you have supplied to us throughout our first session. The initial pricing information is provided transparently and provides you the chance to decide in your price range. During operation, tanks endure corrosion each on the outside and on the within.

essential elements of water tank painting projects

Due to our intensive coaching, our teams tackle a complete strategy from planning to finishing each project. Our project managers will work intently with you and answer any questions you might have. Tnemec’s HydroFlon was chosen to guard the outside of the Warrenville, IL waterspheroid as a outcome of it provides superior long-term colour and gloss retention. Apart from this, all components exposed to open air under the influence of reasonably aggressive setting, also wants to be scalded along the sides to keep away from look of hole spaces and spacing gaps. All internal parts of the tank, welded to the shell, bottom or roof, need to be scalded along the edges to keep away from appearance of hole areas and spacing gaps.

AWWA D102-11 Coating Steel Water-Storage Tanks (PDF)

Because this matter can actually be so much to digest, the American Water Works Association (AWWA) provides a big selection of useful resources, including the AWWA D information for coating steel water-storage tanks. This guide covers every little thing from pre-construction primer choices, to different varieties of inside and exterior coating systems. For the needs of this blog post, Section 4.3 for Exterior Coating Systems offers seven coating system choices with mil thicknesses, typically ranging from 5.5 to 6.5 mils. In phrases of cost-effectiveness, an overcoat system may be sufficient for extending service life within the quick time period. This just isn't an equal substitute for industrial blasting to bare substrate and ranging from scratch, given the service life of coatings are thought of proportional to the floor prep involved.

Man lifts can then be driven in by way of the opening, eliminating the necessity to construct a staging system. Once the job is usually completed, the door is welded again onto the tank and coated final. This method, although typically requiring the companies of a subcontractor for cutting and welding, may be properly worth it for the time that it saves. On jobs involving smaller tanks, staging methods are often constructed contained in the tank itself. A T-system, consisting of two decide boards arranged perpendicular to a minimum of one another and managed by three motors, can increase crews to the appropriate working level.

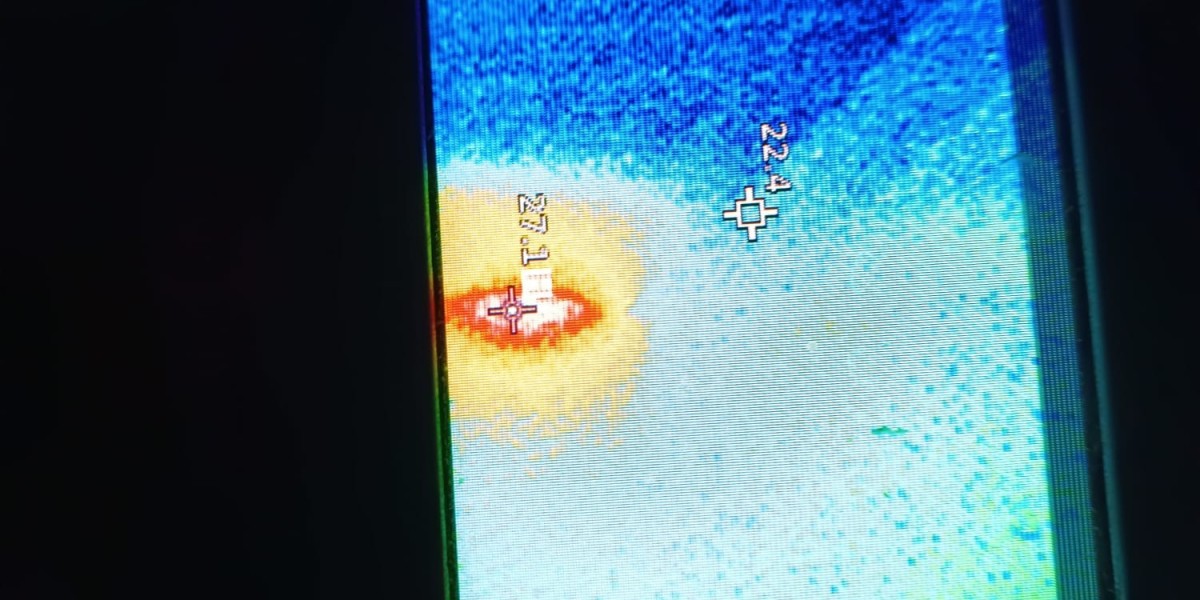

Methods of Storage Tank's Corrosion Protection

Anodes are represented by electrodes of extra electronegative materials, linked to the underside of the protected building. In both situation, we take all elements into account and tailor-fit our coatings to finest protect your tanks/assets and subsequently give them the absolute best protection. With our professional restoration workers, top-of-the-line tools, and use of high notch coatings. We’re very assured in our capability to give you a paint job that will last.

Most paints must be combined to create correct durability and avoid negative chemical reactions. It’s important to finish every step of the metal structure portray course of because improper portray will trigger issues over time. If the metallic frameworks of tank roof and upper rings of the shell present extremely high tempo of corrosion course of it is possible to use inert-gas ambiance as extra technique of corrosion safety. Moreover, you want to present periodic examination of the full surface of the tank not lower than as quickly as in every 5 years for revealing corrosion injury and the areas of floor with broken pain coating. Through the years, we’ve spent 1000's of hours engaged on tanks of all sizes and shapes honing and streamlining our service. We’re committed to delivering thorough and efficient cleaning options that improve safety, keep equipment longevity, and guarantee compliance with industry standards. YP - The Real Yellow PagesSM - helps you discover the best native companies to fulfill your specific wants.